1. Introduction: Why ISO Certification Matters in Modern Business

In today’s global market, customers have more options, more information and higher expectations than ever before. Whether you run a small service firm or a growing manufacturing unit in India or abroad, clients want proof that your systems are reliable, safe and consistent. That is where ISO Certified Companies vs Non-Certified Companies become an important conversation. ISO certification signals that a company follows internationally accepted standards for quality, safety or information security, instead of depending only on internal habits or experience.

At the same time, many Non-Certified Companies still operate successfully using their own internal processes. For business owners, the real question is not just “Do I need a certificate?” but “What difference will it actually make to my daily operations and long-term growth?”. In this blog, we will break down the key differences, practical benefits, costs and limitations, so you can decide whether ISO certification is a strategic step for your company or not.

2. What Is ISO Certification?

ISO stands for the International Organization for Standardization, a global body that creates common standards so companies across countries can work in a consistent, reliable way. An ISO standard is simply a documented best practice for how a system should be managed, while ISO certification is a formal confirmation that a specific company follows that standard in its daily operations.

When people talk about ISO Certification for Companies, they usually refer to well known standards like ISO 9001 for quality management, ISO 14001 for environmental management and ISO 27001 for information security. A certified organisation is independently audited by an external body to check whether its processes, documentation and records match the chosen standard.

These certifications are not limited to factories alone. Manufacturing units, IT companies, startups, healthcare providers, logistics firms and service businesses can all adopt ISO standards. The core idea is simple – create clear processes, monitor performance and continuously improve, so customers receive the same level of quality every single time. For many growing organisations, ISO certification becomes a practical tool to build trust with large clients, qualify for government or corporate tenders and bring internal discipline to fast expanding teams.

3. Understanding ISO Certified Companies

ISO certified companies are organisations that have been formally audited and approved by an accredited certification body against one or more ISO standards. In simple terms, an ISO certified company has documented how its work is done, trained its teams to follow those methods and regularly checks whether reality matches what is written on paper. This creates discipline, traceability and clarity in everyday operations, instead of relying only on memory or individual style.

For most ISO Certified Companies, every important activity – from receiving enquiries and handling complaints to purchasing materials and delivering services – is mapped into procedures, work instructions and checklists. Internal audits, management reviews and corrective actions are used to identify gaps and fix them before they grow into bigger issues. Over time, this approach reduces risks such as rework, delays, safety incidents and data breaches.

You will find ISO certified companies across sectors like manufacturing, construction, IT services, BPOs, healthcare, logistics, education services and facility management. For clients, working with an ISO certified partner often means better consistency, reliable timelines and clearer communication. For the company itself, certification becomes a framework to sustain quality even when the team grows, new people join or new locations are added, which is especially important for ambitious, growth focused businesses.

4. Understanding Non-Certified Companies

Non-certified companies are businesses that operate without an official ISO certificate, but that does not automatically mean they work carelessly or without any system. Many small and mid sized firms build their own internal methods based on experience, customer feedback and industry culture. They may maintain checklists, conduct informal reviews and train staff, but there is no external body verifying whether these practices match a recognised international standard.

In such organisations, quality often depends heavily on the owners, senior managers or a few key employees. This can make decision making faster and give flexibility to adapt quickly when customers request something new. However, the same flexibility can create variation from one project to another if processes are not clearly documented. Different teams may follow slightly different ways of working, which can affect consistency, timelines or service levels.

For some Non-Certified Companies, this works fine when the team is small and client expectations are simple. But as the business grows, hidden risks start to appear: repeated mistakes, difficulty training new staff, confusion over responsibilities and weak records when something goes wrong. Without a structured framework like ISO, it can be harder to prove reliability to large corporate clients, international buyers or government agencies who prefer partners with visible, standard driven systems.

5. Key Differences Between ISO Certified and Non-Certified Companies

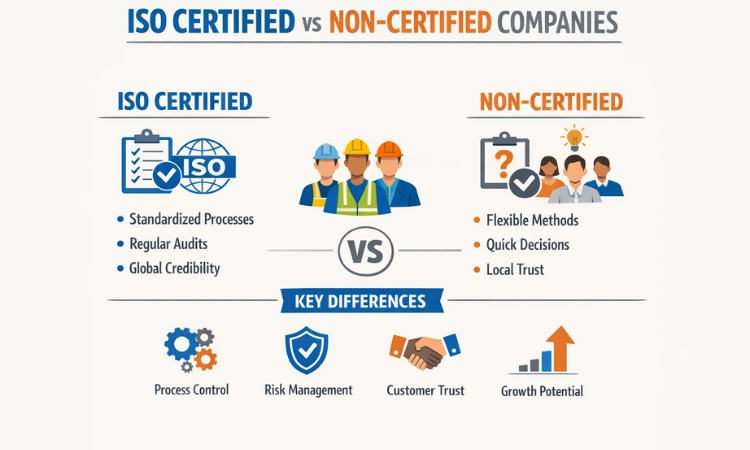

When you compare ISO Certified vs Non-Certified Companies, the real gap is not just a logo on a website. The difference shows up in how work is planned, executed, monitored and improved every day. Below are the main areas where certified and non-certified organisations usually differ.

5.1 Process Standardization

In an ISO certified company, core processes are defined, documented and trained across teams. There are written procedures, formats and checklists for activities like order handling, purchasing, production, service delivery and complaint management. This documentation makes work repeatable and reduces dependence on individual memory.

In many non-certified companies, processes are often understood verbally and passed through experience. People “know” how things are done, but it may not be written clearly. This can work in a small team, but as staff change or new branches open, variation creeps in. Over time, undocumented processes increase the risk of human error, inconsistent output and confusion when something goes wrong.

5.2 Quality Management Approach

ISO certified companies usually follow a preventive quality mindset. They plan quality at the beginning, identify risks, set quality objectives and track performance through data, audits and reviews. Customer feedback, non-conformities and complaints are analysed to understand the root cause and avoid repetition.

Non-certified companies may focus more on reacting to problems after they occur. Quality is often controlled at the end of the process, for example by final inspection or last minute corrections. Without a structured quality management system, it becomes harder to track trends or measure how well the company is actually performing over time.

5.3 Compliance and Risk Management

ISO standards require companies to identify legal, regulatory and contractual requirements and keep records to show compliance. Certified organisations tend to be better prepared for audits from customers, regulators or internal stakeholders because they maintain traceable documentation and defined controls.

In non-certified companies, compliance may depend heavily on the knowledge of a few senior people. Documentation is often scattered, and risks like safety, data protection or environmental impact may not be formally assessed. This can create surprises during external inspections or when entering new markets with stricter regulations. Over the long term, weak risk management can slow down growth and damage reputation.

5.4 Customer Trust and Market Credibility

For many buyers, especially large corporates and international clients, ISO certification acts as a quick trust signal. It shows that the company has gone through an independent check and follows recognised standards. ISO certified companies are often eligible for more tenders, preferred vendor lists and long term contracts because clients feel safer choosing them.

Non-certified companies can still earn strong trust through honest work, references and local relationships. However, when competing in new markets or bidding for large projects, the absence of certification can become a disadvantage. Decision makers reviewing multiple proposals may favour certified suppliers because it reduces perceived risk. This is one of the most visible differences in the ISO Certified vs Non-Certified Companies debate.

5.5 Operational Efficiency

ISO certified companies are encouraged to measure performance, reduce rework and streamline processes. Over time, this focus on efficiency often leads to lower wastage, better utilisation of resources and smoother handovers between departments. Even small improvements, when repeated daily, can add up to significant time and cost savings.

Non-certified companies may also become efficient through experience and a strong operations team. But without structured monitoring, many hidden inefficiencies remain unnoticed – frequent rework, repeated follow ups, unclear instructions or waiting time between steps. These issues increase internal cost even if they are not visible on paper, impacting profitability and capacity.

5.6 Employee Roles and Accountability

In ISO certified companies, roles and responsibilities are clearly defined. Job descriptions, responsibility matrices and internal audits help teams understand who is accountable for which task. Training records and performance indicators are used to build capability and ensure that people are competent for the work they do.

In non-certified setups, work allocation is often more informal. This can create flexibility but may also lead to overlap, gaps or finger pointing when something fails. Without written clarity, employees can find it harder to see how their work connects to the company’s larger goals. Over time, this affects ownership, consistency and the ability to scale.

Together, these points show that the main separation between ISO Certified vs Non-Certified Companies lies in structure, predictability and long term reliability, rather than size or industry alone.

6. Impact on Business Growth and Scalability

When a company wants to grow beyond a small local setup, systems matter more than individual talent. One of the biggest Benefits of ISO Certification is that it creates a common way of working which can be replicated across new branches, new cities and even new countries. Because processes, records and responsibilities are clearly defined, it becomes easier to train new people, add new teams and still deliver the same level of quality everywhere.

For growing organisations, ISO certified companies often find it simpler to win larger clients, enter international supply chains or partner with multinational firms that demand documented systems. Internal alignment also improves – sales, operations, purchase, HR and accounts know what is expected from them at each step. This reduces internal friction and frees up leadership time to focus on strategy instead of daily firefighting.

Non-certified companies can also grow, but scaling usually depends on a few strong individuals and informal controls. As volume increases, this model starts showing cracks. In contrast, an ISO based management system gives a stable backbone for long term, sustainable growth. This helps businesses grow with confidence.

7. Cost Considerations

When leaders think about ISO certification for companies, the first question is usually about cost. There are three main components to consider: internal preparation, consultant or training fees if used and external certification and surveillance audit charges. For a smaller organisation, this can feel like a big one time investment plus a yearly renewal cost. However, the purpose of certification is not just to get a certificate on the wall, but to reduce daily waste, rework and confusion through better systems.

On the other side, non certified operations carry their own hidden costs. Lack of standard processes often leads to repeated mistakes, delayed deliveries, customer complaints and higher employee stress. These issues consume management time and sometimes result in lost orders or penalties, even though they never appear as a clear line item in the budget.

The practical way to look at ISO certification for companies is to treat it as a value decision, not only an expense. If your clients demand higher reliability, documentation and compliance, the structured approach of ISO can pay back over time through smoother work, stronger reputation and better access to high value contracts.

8. Industry-Specific Relevance of ISO Certification

Across industries, ISO certification does not look the same, but the need for structured systems is universal. In manufacturing, ISO Certified Companies typically adopt ISO 9001 for quality and ISO 14001 for environment to control defects, wastage, safety and regulatory compliance. Standardised processes, calibration and traceability are critical when you are producing components, food products, machinery or packaging at scale.

In IT and technology services, ISO 27001 for information security and ISO 20000 for service management are often preferred. Clients trust ISO Certified Companies to handle sensitive data, uptime, incident response and continuity planning with clear, audited controls. This can be the difference between winning and losing enterprise level projects.

Healthcare, diagnostics and medical device sectors rely heavily on standard driven systems because errors can directly affect patient safety. Hospitals, labs and suppliers use ISO standards to manage hygiene, documentation, equipment maintenance and reporting.

Service industries such as logistics, facility management, training and consulting are also moving towards ISO frameworks to differentiate themselves in a crowded market. For them, certification proves that delivery, feedback handling and continual improvement are not just promises in a brochure, but part of how the organisation works every day. Even in government projects and public utilities, ISO Certified Companies are increasingly preferred because they offer traceability, transparency and predictable service levels.

9. Common Myths About ISO Certification

Many business owners hesitate to explore ISO certification because of a few common misunderstandings. One popular myth in the ISO Certified vs Non-Certified Companies debate is that certification is only meant for very large organisations. In reality, a clear, standard based way of working is often even more helpful for small and mid sized firms that are trying to grow in an organised manner.In India, this misunderstanding often leads to some of the most common mistakes to avoid during ISO certification, such as delaying documentation, underestimating internal readiness or assuming certification is only for large enterprises.

Another misconception is that ISO certification automatically guarantees success, orders or profits. The certificate is only a tool – results still depend on leadership, market strategy and daily execution. ISO helps bring discipline and clarity, but it does not replace good management.

Some leaders also fear that ISO will make their company rigid and kill creativity. In practice, standards ask you to document how you work and improve it regularly; they do not stop innovation. Well implemented systems create a stable base, so your teams can experiment safely without losing control of quality or compliance.

10. When Should a Company Consider ISO Certification

A company should start seriously thinking about ISO certification when it has moved beyond trial-and-error and is ready to grow in a structured way. Typical signs include repeated quality issues, frequent customer escalations, difficulty training new staff or confusion between departments about “who is responsible for what”. At this stage, a recognised framework like ISO helps bring order, clarity and shared discipline.

Another clear trigger is client demand. Many large Indian corporates, MNCs and government bodies now list ISO certification as a requirement in their tenders and vendor registration forms. If your sales team keeps hearing this condition, it is time to explore ISO Certification for Companies as a strategic step, not just a marketing label.

ISO also becomes relevant when you want to enter export markets, supply to critical sectors like healthcare or infrastructure, or attract investors who care about governance and risk control. In all these cases, certification signals that your organisation is mature enough to handle growth responsibly.

11. ISO Certified vs Non-Certified: Which Is Better? (Neutral Perspective)

When comparing ISO Certified vs Non-Certified Companies, there is no single verdict that fits every business. The value of certification depends on your industry, size, customer base and growth plans. For organisations working in regulated sectors, dealing with global clients or aiming for large institutional contracts, ISO certification can be a strong strategic asset. It offers structure, documented assurance and a clear signal of reliability to the market.

At the same time, some early stage startups, local service providers or niche specialists may operate effectively without formal certification, especially when they serve a small, known customer base and can respond quickly through personal relationships. For them, immediate flexibility may feel more important than structured documentation.

The key is to view ISO as a management tool, not a compulsory badge. If your long term vision includes scaling up, entering new markets or building a professional brand, certification can support that journey. If not, strengthening internal systems is still essential, with or without ISO.

12. Conclusion: Making an Informed Decision

Choosing between certification and non-certification is really about choosing how you want your business to grow. The discussion of ISO Certified Companies vs Non-Certified Companies is not about right or wrong, but about structure, risk and long term vision. ISO Certified Companies work with documented systems, regular audits and a preventive approach to quality, highlighting the importance of ISO certification in supporting scalability, customer trust, regulatory compliance and tender eligibility. Non-certified companies may move faster in the short term, but often rely heavily on a few key people and informal controls.

Instead of chasing a logo, evaluate where you are today, what your customers expect and where you want to be in the next 3–5 years. When certification is aligned with clear business objectives, it becomes a practical investment in stability, credibility and sustainable growth.